Long Travel Suspension

Contents

- 1 Long Travel Suspension: A Deep Dive

- 1.1 Definition and Types of Long Travel Suspension

- 1.2 Components of Long Travel Suspension Systems

- 1.3 Impact of Long Travel Suspension on Vehicle Performance

- 1.4 Design and Engineering Considerations

- 1.5 Maintenance and Modifications

- 1.6 Applications and Examples in Different Industries, Long travel suspension

Long Travel Suspension: A Deep Dive

Long travel suspension systems are designed to provide significantly more wheel travel than standard suspension setups, allowing for greater articulation and ground clearance. This is crucial for vehicles navigating rough terrain, where maintaining tire contact with the ground is paramount. This article will explore the intricacies of long travel suspension, from its fundamental principles to its practical applications across various industries.

Definition and Types of Long Travel Suspension

Long travel suspension, in simple terms, allows a vehicle’s wheels to move up and down through a much greater distance compared to a standard suspension system. This increased travel range is achieved through longer suspension arms, stronger components, and often a different suspension geometry. Standard suspensions prioritize comfort and on-road handling, while long travel prioritizes off-road capability and articulation.

Vehicles commonly equipped with long travel suspension include off-road trucks, desert racers, rock crawlers, and some motorcycles designed for extreme terrain. Specific examples include trophy trucks, prerunner vehicles, and specialized all-terrain vehicles (ATVs).

Several types of long travel suspension exist, each with its own mechanism and best-suited application. Common types include long-arm, trailing-arm, and various independent suspension designs incorporating longer travel components. Long-arm systems use long control arms to achieve increased travel, offering good articulation and stability. Trailing-arm systems are simpler but may offer less articulation. Independent systems, such as those employing a-arms or radius rods, allow each wheel to move independently, improving handling and traction.

| Suspension Type | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Long-Arm | Excellent articulation, good stability | Complex design, higher cost | Off-road trucks, rock crawlers |

| Trailing-Arm | Simple design, lower cost | Limited articulation, potential for axle wrap | Simple off-road vehicles, some ATVs |

| Independent (A-arm/Radius Rod) | Superior handling, good articulation | More complex design, higher cost | High-performance off-road vehicles, some motorcycles |

Components of Long Travel Suspension Systems

A long travel suspension system comprises several key components working in concert to provide extended wheel travel. Understanding the function of each component is crucial for maintenance, modification, and troubleshooting.

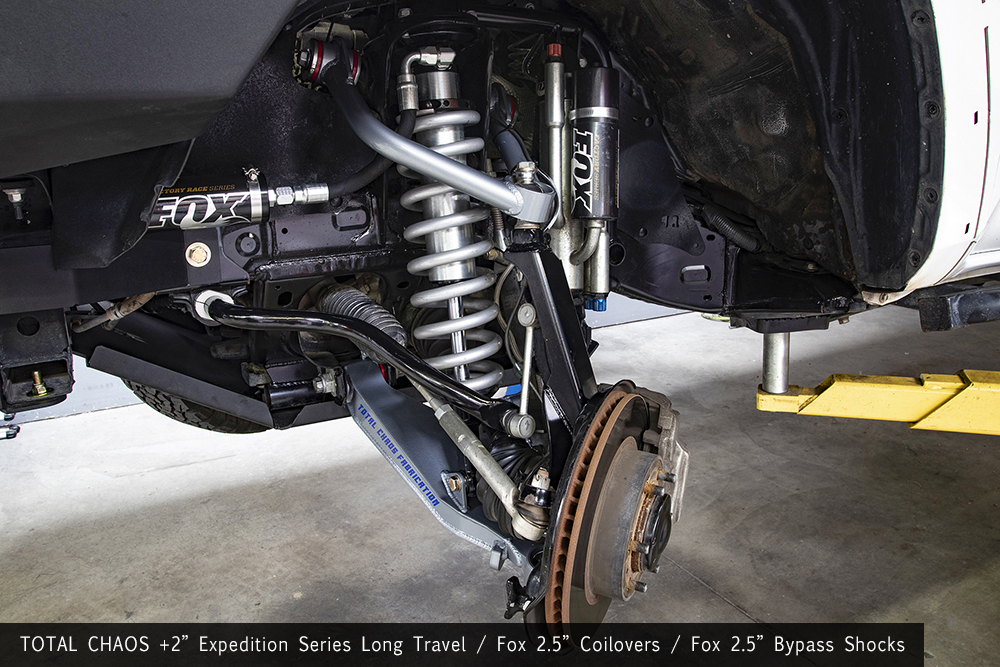

- Control Arms/A-Arms: These long arms connect the chassis to the axles or suspension hubs, dictating the suspension’s geometry and travel.

- Shocks/Struts: These dampening devices control the rebound and compression of the suspension, preventing harsh impacts and maintaining control.

- Springs: These provide the primary support for the vehicle’s weight and absorb impacts, often coil springs or leaf springs in long travel systems.

- Bushings/Bearings: These allow for smooth articulation between components, reducing friction and wear.

- Axles/Hubs: These connect the wheels to the suspension, transferring power and supporting the vehicle’s weight.

Materials like high-strength steel, chromoly, and aluminum alloys are commonly used for their strength-to-weight ratio and durability. The choice of material significantly impacts the system’s weight, strength, and longevity.

A diagram of a long-arm long travel suspension would show the long control arms extending from the chassis to the axle, with shocks and springs attached. The interaction between the components would be clearly illustrated, showing how the suspension geometry allows for significant up and down movement of the wheels. The diagram would highlight the pivotal points and the pathways of motion for each component during articulation.

Impact of Long Travel Suspension on Vehicle Performance

Long travel suspension profoundly impacts vehicle performance, particularly in off-road situations. The increased wheel travel allows for better traction and stability on uneven terrain by maintaining tire contact with the ground. This improves handling and reduces the risk of getting stuck. The ride quality, while often firmer than a standard suspension, is generally more controlled and less jarring over rough surfaces.

Vehicle articulation, the ability of the wheels to move independently, is significantly enhanced with long travel suspension. This allows the vehicle to navigate obstacles more effectively, maintaining traction even when one wheel is significantly higher or lower than others. Ground clearance also increases, reducing the risk of bottoming out on obstacles.

In off-road scenarios, long travel suspension is crucial for maintaining control and preventing damage to the vehicle. Examples include navigating rocky trails, traversing deep ruts, and climbing steep inclines. The increased articulation allows all four tires to remain in contact with the ground, even on uneven terrain, which is crucial for maintaining traction and stability.

Design and Engineering Considerations

Designing a long travel suspension system presents several engineering challenges. The primary concern is to balance the need for increased travel with the requirements for vehicle stability and handling. Suspension geometry, component strength, and the interaction between components must be carefully considered. The choice of components is also crucial, with strength and durability being paramount.

Suspension travel is calculated based on the geometry of the suspension system and the length of the components. Optimization involves finding the optimal balance between travel, stability, and ride quality. This often involves iterative design and testing to fine-tune the system’s performance.

- Suspension Geometry: This determines the motion ratio and articulation of the suspension.

- Component Strength: Components must be strong enough to withstand the forces generated during extreme travel.

- Shock Valving: This determines the damping characteristics of the shocks.

- Spring Rate: This determines the stiffness of the springs.

- Anti-squat and Anti-lift Geometry: These affect the vehicle’s handling during acceleration and braking.

These parameters are interdependent, and changes in one parameter will affect the others. Careful consideration of these interdependencies is essential for a well-performing system.

Maintenance and Modifications

Regular maintenance is crucial for the longevity and performance of a long travel suspension system. This involves periodic inspection and lubrication of components, as well as checking for wear and tear.

- Inspect all components for damage or wear.

- Lubricate bushings and bearings.

- Check shock absorbers for leaks or damage.

- Inspect springs for breakage or sagging.

- Check and adjust alignment.

Common problems include worn bushings, leaking shocks, and broken springs. Troubleshooting involves identifying the faulty component and replacing or repairing it. Modifications to a long travel suspension system may involve upgrading to stronger components, adjusting spring rates, or changing shock valving to fine-tune performance for specific applications.

A maintenance checklist should include regular inspections of all components, lubrication, and adjustments as needed. This ensures the system remains in optimal condition and prevents unexpected failures.

Applications and Examples in Different Industries, Long travel suspension

While prominently featured in off-road vehicles, long travel suspension finds applications in other industries where increased ground clearance, articulation, and stability are needed. These include agricultural machinery, construction equipment, and even some specialized transportation vehicles.

In agriculture, long travel suspension can be found on tractors and harvesters operating in uneven fields. This improves stability and reduces damage to crops. Construction equipment, such as excavators and loaders, may utilize long travel suspension to maintain stability on uneven terrain and improve operator comfort. Specialized vehicles, such as those used in disaster relief or military operations, might also incorporate long travel suspension for increased mobility and off-road capabilities.

The design and performance requirements vary across industries, depending on the specific application and environmental conditions. Adapting long travel suspension technology for novel applications requires careful consideration of these factors and may involve innovative design solutions to meet specific needs.